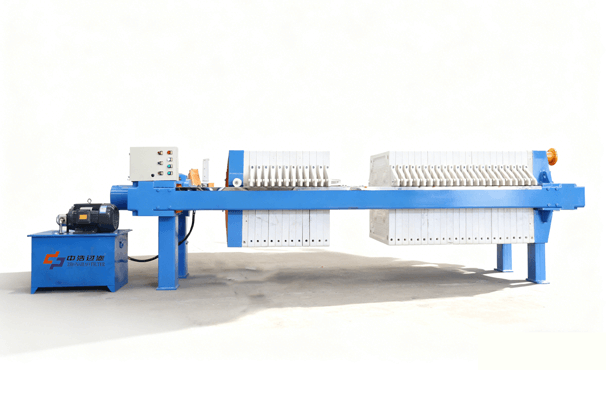

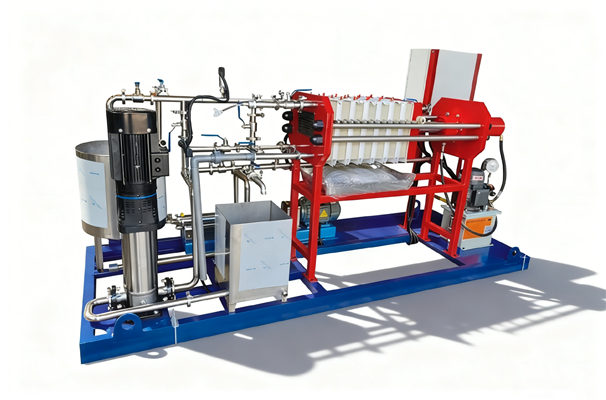

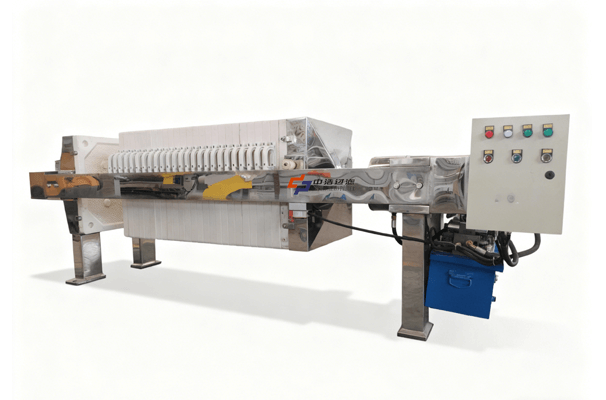

With deep expertise in the biopharmaceutical sector, we have served over 400 clients. In active pharmaceutical ingredient (API) production, our solutions specialize in filtering, washing, and pre-drying dewatering for crystalline APIs (e.g., antibiotics, vitamins), fermentation residues (mycelium), and intermediates. In traditional Chinese medicine (TCM) manufacturing, we efficiently handle the concentration and filtration of herbal extracts, as well as solid-liquid separation of medicinal residues. Additionally, our technologies are widely applied in biological products, including the separation processes for enzymes, amino acids, yeast, and similar products. Leveraging professional filtration expertise, we deliver efficient and reliable solutions to pharmaceutical enterprises.

Overview of Our Professional Capabilities and Client Cooperation

Boasting profound professional expertise in the Biopharmaceutical sector, we have established long-term cooperative relationships with more than 400 clients, providing high-quality filtration and separation solutions tailored to the unique needs of pharmaceutical production. Our filter press technologies have been widely recognized for their efficiency, reliability, and compliance with industry standards, playing a pivotal role in optimizing production processes and ensuring product quality across multiple biopharmaceutical segments.

Application in Active Pharmaceutical Ingredients (APIs) Production

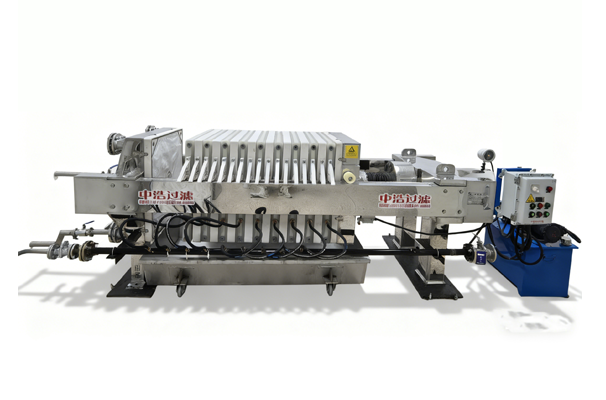

In the production of Active Pharmaceutical Ingredients (APIs), our filter press solutions are specifically engineered for the key processes of filtering, washing, and pre-drying dewatering. They are highly applicable to crystalline APIs such as antibiotics and vitamins, as well as fermentation residues (including mycelium) and various pharmaceutical intermediates. By adopting advanced filtration mechanisms, our equipment effectively removes impurities, reduces moisture content in materials, and enhances the purity of APIs, laying a solid foundation for subsequent processing steps.

Application in Traditional Chinese Medicine (TCM) Manufacturing

In Traditional Chinese Medicine (TCM) manufacturing, our filter presses deliver efficient processing capabilities for herbal extracts and medicinal residues. They excel in the concentration and filtration of herbal extracts, effectively separating active ingredients from impurities to improve extract quality. Meanwhile, they achieve precise solid-liquid separation of medicinal residues, facilitating the comprehensive utilization of herbal resources and reducing environmental pollution.

Application in Biological Products Production

Additionally, our cutting-edge technologies are extensively applied in the production of biological products. They are widely used in the separation processes of enzymes, amino acids, yeast, and other related products, ensuring high separation efficiency and product activity.

Our Commitment to the Biopharmaceutical Industry

Leveraging our professional filtration expertise and rich industry experience, we are committed to providing biopharmaceutical enterprises with customized, efficient, and reliable filter press solutions, contributing to the high-quality development of the Biopharmaceutical industry.