We have served over 100 clients in the new materials and new energy sectors, processing materials such as lithium batteries, graphite, photovoltaic products, barium carbonate, and sodium carbonate. By efficiently addressing their filtration needs, we have consistently received positive feedback from all customers!

Overview of Our Expertise and Client Services in Lithium Battery Graphite Sector

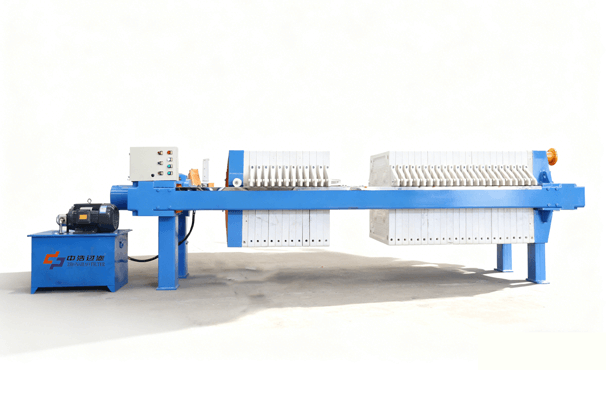

As a core anode material for lithium-ion batteries, lithium battery graphite—a pivotal product in the advanced materials and new energy sector—imposes extremely stringent requirements on purity, particle size distribution, and moisture content. With years of rich expertise in this field, we have served numerous new energy enterprises and provided tailored filter press solutions for lithium battery graphite production, which play a crucial role in optimizing production processes and ensuring stable product quality.

Key Applications of Our Filter Presses in Lithium Battery Graphite Production

Our filter press equipment is widely applied in three key links of lithium battery graphite production: first, ore pulp filtration, which efficiently separates graphite concentrate from gangue impurities to improve raw material grade; second, concentrate washing, which removes ash, metal, and other harmful impurities with low water consumption, a step critical for enhancing the electrochemical performance of lithium battery graphite; third, post-purification dewatering, which lays a solid foundation for subsequent processing procedures.

Core Advantages of Our Filter Press Solutions for Lithium Battery Graphite

Notably, our filter presses can stably control the moisture content of lithium battery graphite below 8%, effectively avoiding adverse impacts on subsequent processes such as graphitization and forming. Compared with traditional separation equipment, our solutions boast higher filtration efficiency, lower energy consumption, and stronger adaptability to lithium battery graphite materials of different particle sizes, supporting continuous production operations.

Our Commitment to Boosting the Advanced Materials and New Energy Sector

Our customized filter press solutions help new energy enterprises significantly improve production efficiency, reduce operating costs, and ensure that lithium battery graphite products fully meet the high standards of the new energy battery industry, thereby boosting the sustainable development of the advanced materials and new energy sector.