We have served over 300 clients in sludge and wastewater treatment for chemical plants and municipal wastewater treatment plants. Our achieved filter cake moisture content can be as low as 15%, with crystal-clear filtrate, consistently receiving positive feedback from customers!

Commonly Used Equipment:

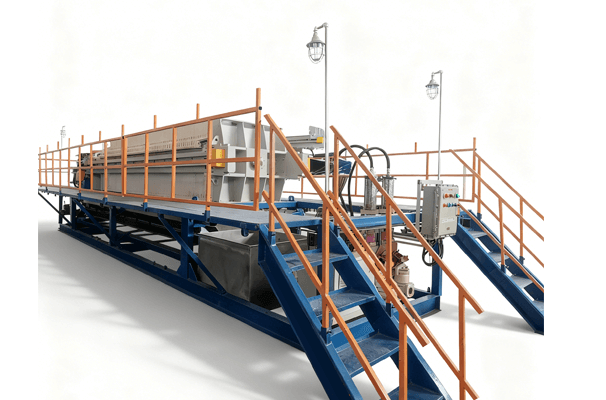

- Fully Automatic Water Washing Diaphragm Filter Press

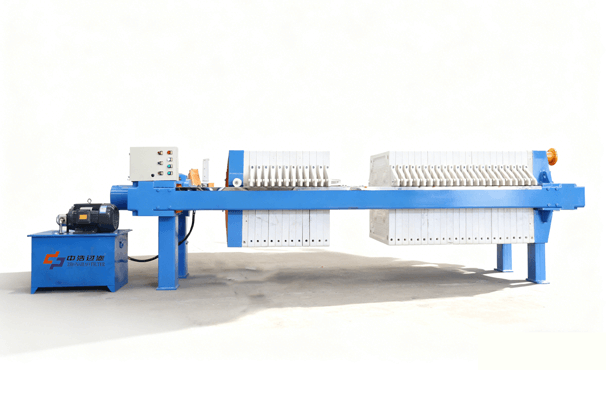

- PLC-Controlled Automatic Plate-Shifting Diaphragm Filter Press

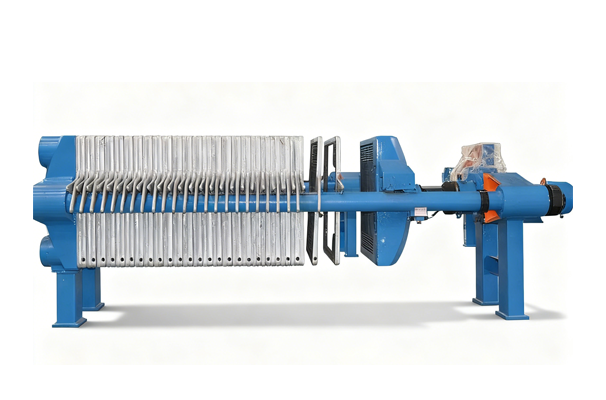

- High-Efficiency Fast-Opening Filter Press

As a core equipment for solid-liquid separation, Zhonghao Filter Press plays an irreplaceable role in municipal and chemical industries, addressing key pain points such as wastewater treatment, sludge disposal, and environmental compliance with tailored performance advantages.

In the municipal industry, Zhonghao Filter Press is mainly applied to sewage treatment plants for sludge dewatering. Municipal sewage contains a large amount of organic sludge from domestic waste and industrial runoff; the equipment efficiently separates moisture from sludge through high-pressure filtration. It handles sludge from primary sedimentation tanks and biochemical treatment systems, reducing sludge volume by over 70% and increasing sludge dryness to 80% or more. This not only minimizes the cost of sludge transportation and landfill but also enables resource utilization—dewatered sludge can be processed into organic fertilizer or building materials. Additionally, the fully automatic control system adapts to the fluctuating sludge volume of municipal sewage, ensuring stable operation without excessive manual intervention.

In the chemical industry, the equipment targets the characteristics of corrosive, toxic, and high-viscosity wastewater from production processes. It is widely used in treating wastewater from chemical reactions, solvent recovery, and pesticide production. Adopting corrosion-resistant materials such as 304 stainless steel and PP coating, it resists erosion from acids, alkalis, and organic solvents. Its precise filtration accuracy (0.1-10μm) effectively retains harmful solids, preventing pollutants from leaking into effluent. For example, in petrochemical plants, it separates catalyst residues and oil sludge, ensuring effluent meets discharge standards and recovering valuable components.

The shared advantages across both industries include exceptional durability, low operational costs, and strong customizability. Its stable performance ensures long-term operation under heavy loads, while energy-saving motors and low-maintenance design reduce operational expenses. Zhonghao also provides customized models for different scales—from small municipal satellite stations to large chemical parks—making it a reliable choice for environmental governance in both sectors.