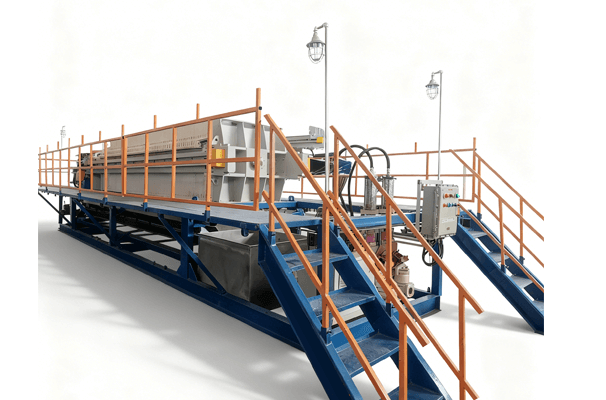

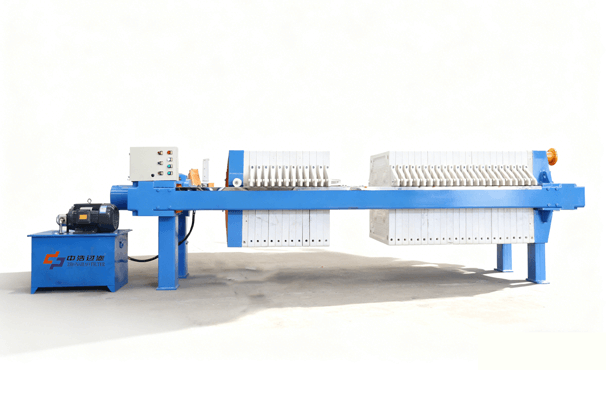

With deep industry expertise and proven strength, our plate and frame filter presses have successfully served over 500 mining and metallurgy enterprises, covering ten major non-ferrous and ferrous metal ores including copper, lead, zinc, gold, silver, iron, tungsten, tin, nickel, and molybdenum. Through efficient and stable solutions, we consistently deliver core value to our clients.

Application Background and Core Role of Filter Presses in Tailings Slurry Treatment

Tailings Slurry, a by-product generated in mining, metallurgy, and mineral processing industries, contains a large amount of water and solid particles. Improper treatment of Tailings Slurry not only causes environmental pollution but also wastes water and mineral resources. As a key equipment for solid-liquid separation, filter presses play an irreplaceable role in Tailings Slurry treatment. With rich experience in industrial solid waste and wastewater treatment, we provide customized filter press solutions for Tailings Slurry processing, helping enterprises achieve green production.

Advantages and Application Value of Customized Filter Press Solutions

Compared with traditional Tailings Slurry treatment methods, our filter press solutions feature higher separation efficiency, stronger adaptability to Tailings Slurry with varying solid contents, and lower operating costs. They effectively solve the problems of Tailings Slurry storage and transportation, reduce the occupation of land resources, and avoid the risk of tailings pond leakage. Our tailored solutions have been widely adopted in many mining projects, helping enterprises meet strict environmental protection standards, reduce resource waste, and realize the dual goals of environmental and economic benefits.