Product Introduction

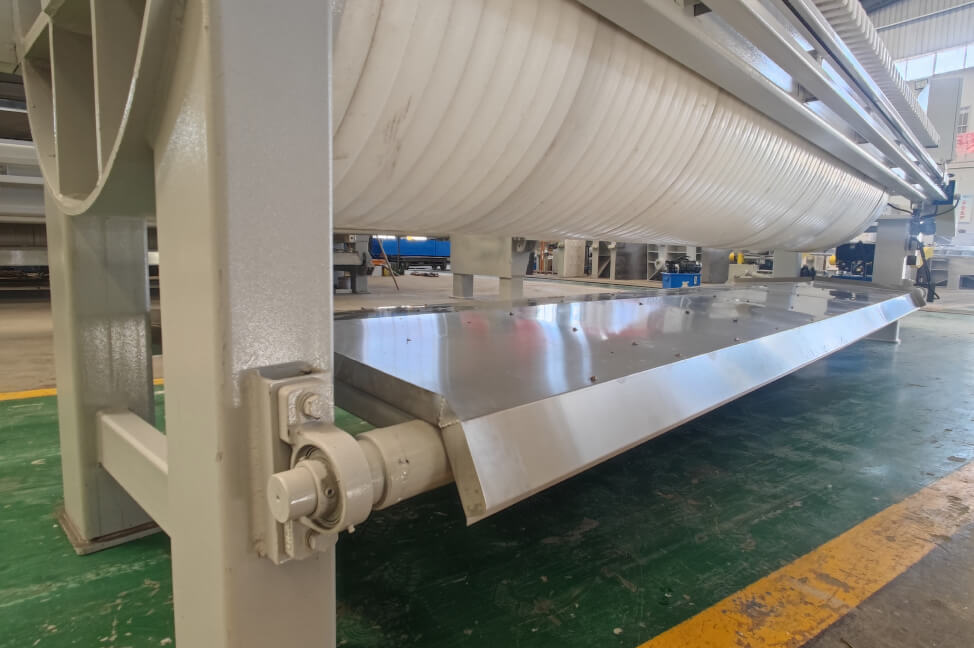

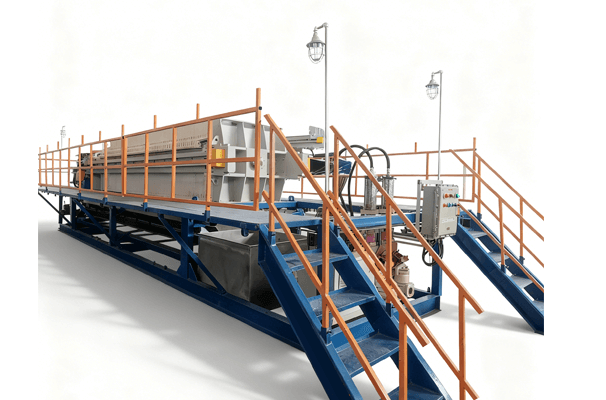

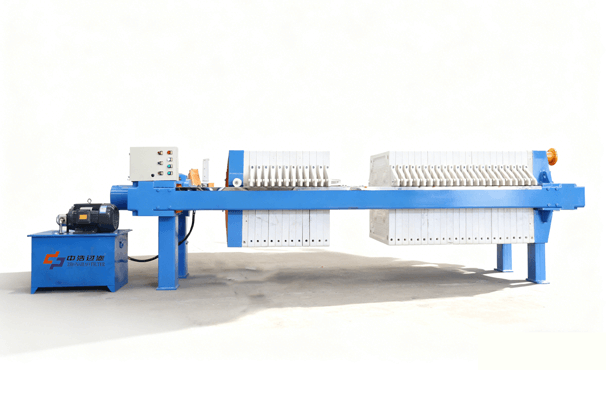

The mobile filter press is an outstanding representative of the “equipment-based, intelligent, and mobile” development trend in the environmental protection field. It perfectly addresses the “last mile” challenge of sludge treatment by transforming the traditional model of “transporting sludge to a treatment facility” into a new model of “bringing the treatment to the sludge,” greatly improving processing efficiency, reducing overall costs and environmental risks, and making it an indispensable technology in today’s environmental market.

Key Features and Advantages

The system can move directly to any sludge site (“treating sludge on-site”) without the need for permanent infrastructure. It is especially suitable for dispersed or temporary work sites.

Once on-site, simply connect the water source and material source (e.g., place the suction hose in the sludge pond), start the generator, and begin work. Deployment time is extremely short.

Users do not need to build permanent dewatering workshops, civil foundations, or piping systems, greatly reducing infrastructure investment and land usage costs.

Treats sludge directly at its source, avoiding secondary pollution such as leakage or spillage during transport of high-moisture sludge (95%-98% water content). The resulting dry cake (≤60% moisture) reduces volume and cuts transportation costs by over 80%.

One mobile filter press can serve multiple dispersed sites (e.g., multiple rivers or small wastewater treatment stations), enabling centralized resource use and rapid relocation between sites.

Highly automated; only 1-2 operators are needed to complete the entire process.

Main Applications

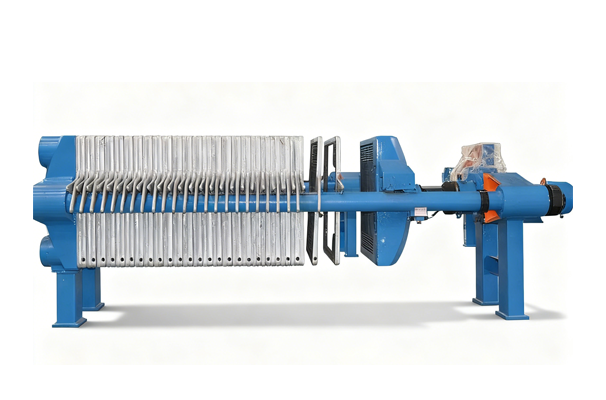

- In the purification of photovoltaic materials (such as silicon, quartz sand) and the recovery of cutting fluid, a large amount of wastewater containing fine particulate matter will be produced.

- Zhonghao filter press can efficiently achieve solid-liquid separation, recover valuable metal powder and cutting fluid, and the moisture content of the filter cake is low, which is convenient for resource utilization.

- In the petrochemical production process, sludge with complex components containing oil and catalysts will be produced.

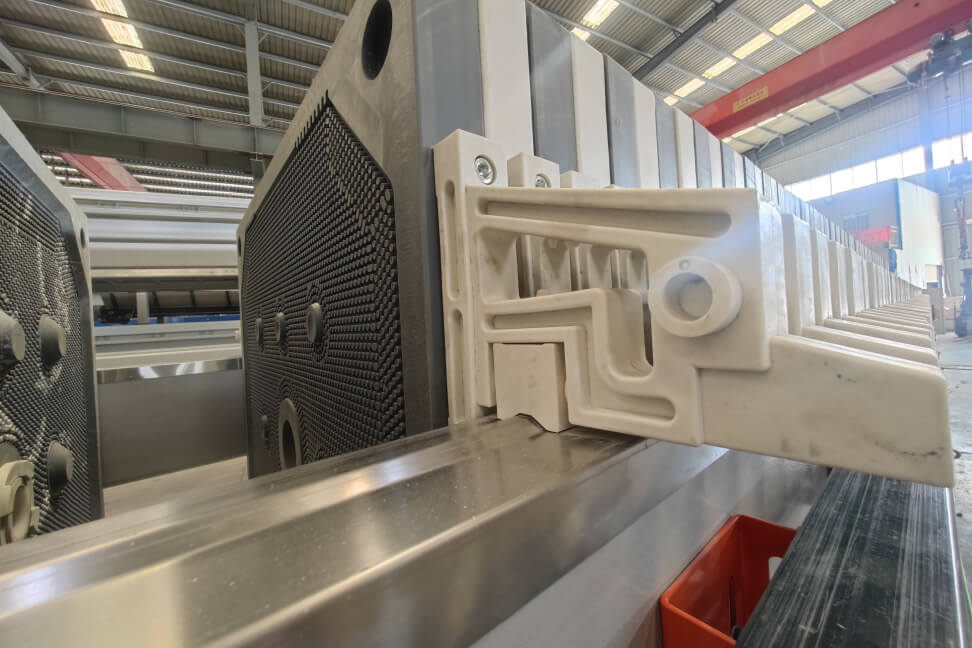

- Zhonghao filter press adopts special filter cloth and optimized structure, which is corrosion-resistant and has good sealing.

- It can efficiently treat such sludge, the filtrate is clear, and the separation is accurate to meet the requirements of environmental protection and discharge.

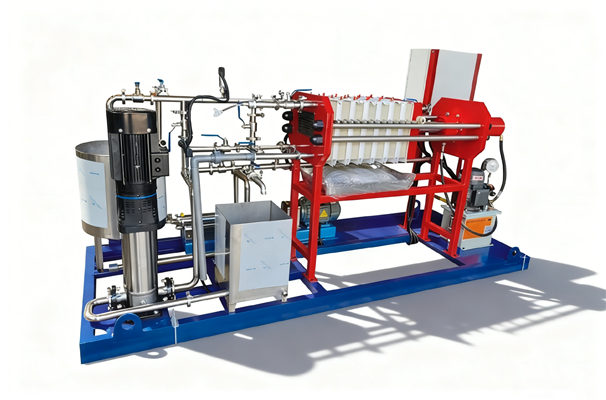

- In food processing (such as starch, juice, yeast) and pharmaceutical (antibiotics, traditional Chinese medicine extraction, fermentation liquid) processes, there are a large number of links that require precise solid-liquid separation.

- Zhonghao filter presses use materials and designs that meet food hygiene standards to ensure quality and safety, efficiently separate and recycle valuable intermediate products or by-products, and ensure the safety and quality of the final product.

- Dehydration is a key part of the biochemical sludge produced by municipal sewage treatment plants.

- Zhonghao filter press equipment has a high degree of automation and stable operation. It can continuously press the flowing sludge into dry and hard mud cakes, greatly reducing the volume and weight of the sludge, creating favorable conditions for subsequent incineration, composting or landfill disposal, and effectively reducing municipal operating costs.

- Facing the mud treatment problems caused by tailings, sand washing, etc., Zhonghao filter press has demonstrated excellent dehydration performance.

- It can compress ore slurry with extremely high moisture content into a sturdy, low moisture content filter cake, reducing the risk of environmental pollution.

- Aquaculture wastewater is rich in nitrogen, phosphorus and organic matter, and direct discharge is extremely harmful.

- The Zhonghao filter press function quickly separates the suspended solids and manurefrom the wastewater to form dry manure residue.

- These manure residues are high-quality raw materials for making organic fertilizers, which realize the resource utilization of waste.

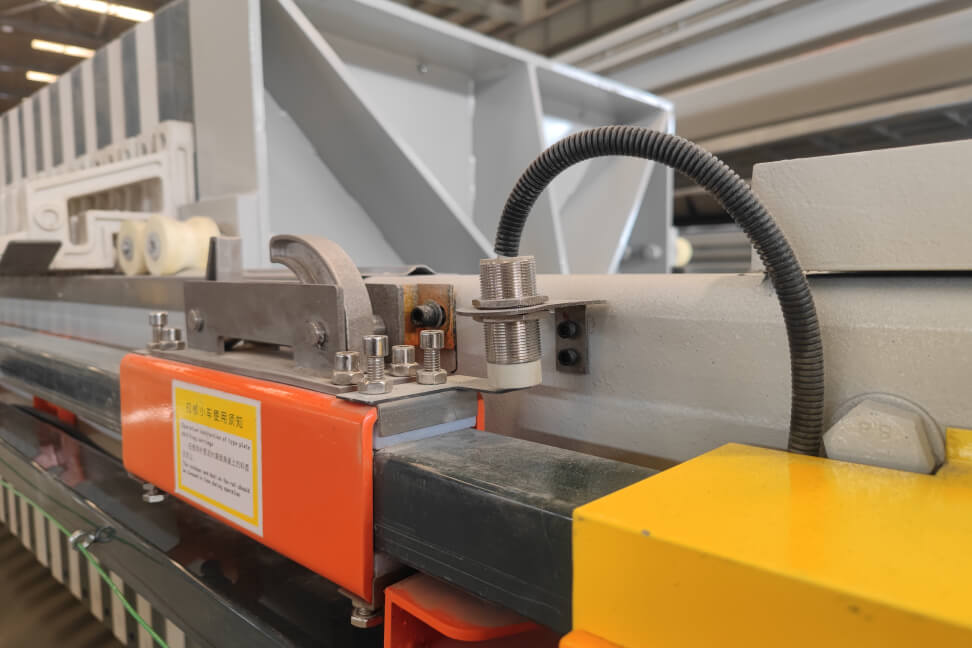

Automation options

Customers can independently select and configure corresponding automation options based on their actual business scenarios to optimize the operational efficiency of automated business processes.

Parameter Information

| Model | Flatbed Truck Size | Configuration | Single Batch Sludge Discharge Volume | N.W(tons) |

| JDZCXMZ200/1250-30U | 13m | Filter press+belt conveyor(including folding operating platform)+removable canopy+slurry pump+mixing tank | 3 m³ | 16 |

| JDZCXMZ500/1500-30U | 17.5m | 7.5 m³ | 37 | |

| JDZCXMZ600/1500-30U | 17.5m | 9 m³ | 41 |